Sustainability report 2023

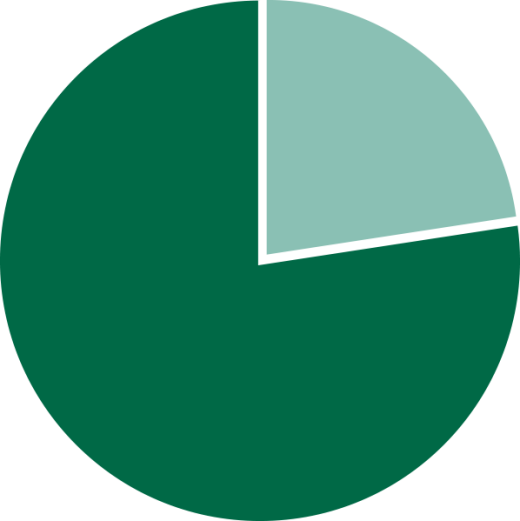

1%

7%

9%

33%

50%

An important step was the hiring of Group Manager Circular Business, Elske Schotte. This has given our solutions for reusable systems a permanent place within the organization.

our film expert Leo van der Meer

Elske Schotte

Group Manager Circular Business

‘How do we see the future? As much reusable packaging as possible, in a circular system, provided this is the best choice based on an LCA study.’

‘Shelf life and sustainability are now just as important as the protective function.’

A circular collaboration:

The Food Line-up

and Paardekooper

The Food Line-up, a B-Corp-certified business caterer with a big focus on impact, likes looking for solutions that not only reduce plastic, but certainly also reduce waste. The Food Line-up did not want to wait for the SUP legislation for events, but wanted to be at the forefront of a solution itself. They chose Paardekooper's reusable alternatives. We spoke to Annemiek de Been, Product Manager at The Food Line-up.

Working together

on sustainability: Paardekooper x Schwartzmans

*Page in Dutch

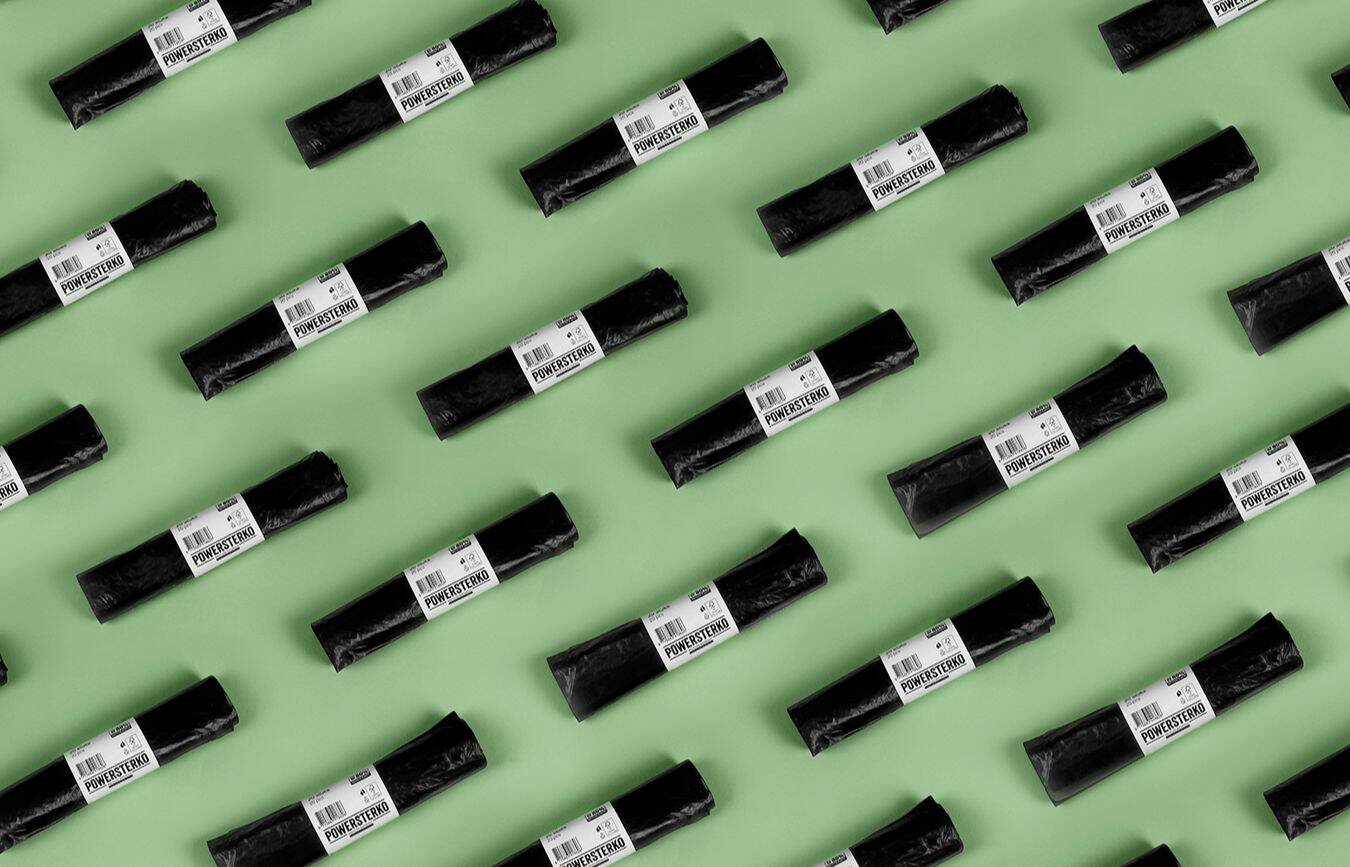

Film is used in different ways. For example, as a flowpack for the packaging of (prepared) vegetables, fruit, meat and dairy products. Or as a topseal on a tray or bowl. Cucumbers and broccoli are also often wrapped in film to reduce food waste.

Making film more sustainable is a very hot topic and developments are moving fast.

In partnership with Schwartzmans, Paardekooper conducted a pilot to evaluate the current assortment and explore possible steps to make it more sustainable. We used our assortment classification for this.

In de komende jaren willen we onze organisatie CO₂-uitstoot halveren.

Materialiteitsanalyse uitgevoerd om onze leidende thema’s te bepalen

phase out

more conscious

METAL

Other

BIOBASED

PAPER/cardboard

MULTI

PLASTIC

Non RECYCLaBle

RECYCLaBle

No Packaging

Packaging

Basic

More sustainable

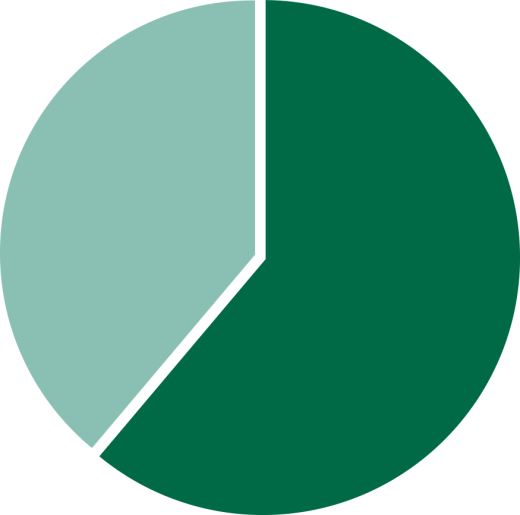

Electricity

company and lease cars

TRUCKS

Electric company and lease cars

GAS

2023

* By the term plastic-free packaging, we mean packaging in which no polymers (plastics) have been used to make the product water- and/or grease-repellent, as defined in the Dutch legislation on Single Use Plastics. If you want to read more about the Dutch Legislation on Single Use Plastics, read more on our special web page.

(and the recycling situation in the Netherlands)

excluding Horti division

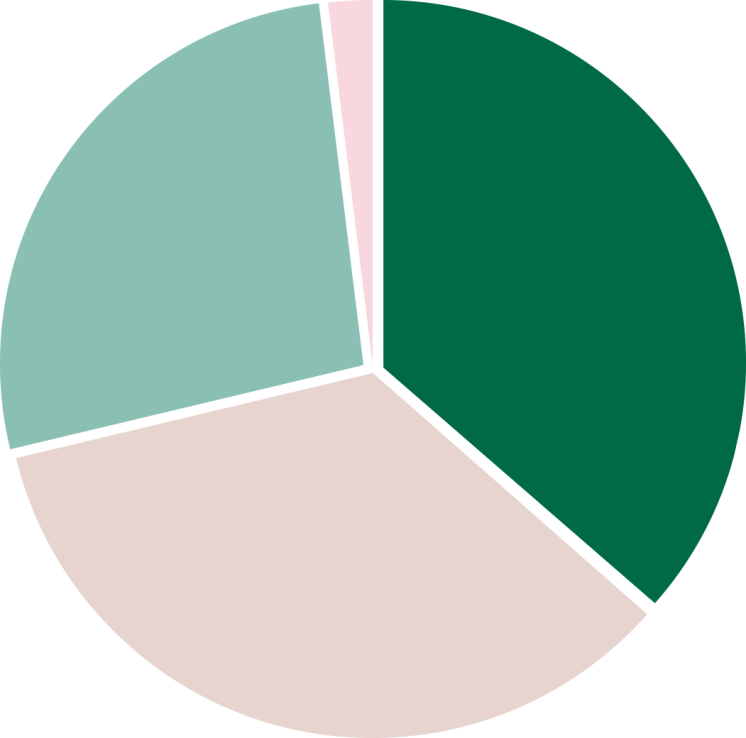

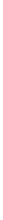

% of packaging THAT IS RECYCLABLE

BASED ON REVENUE

Packaging material types

AS % OF REVENUE

packaging share

% of revenue

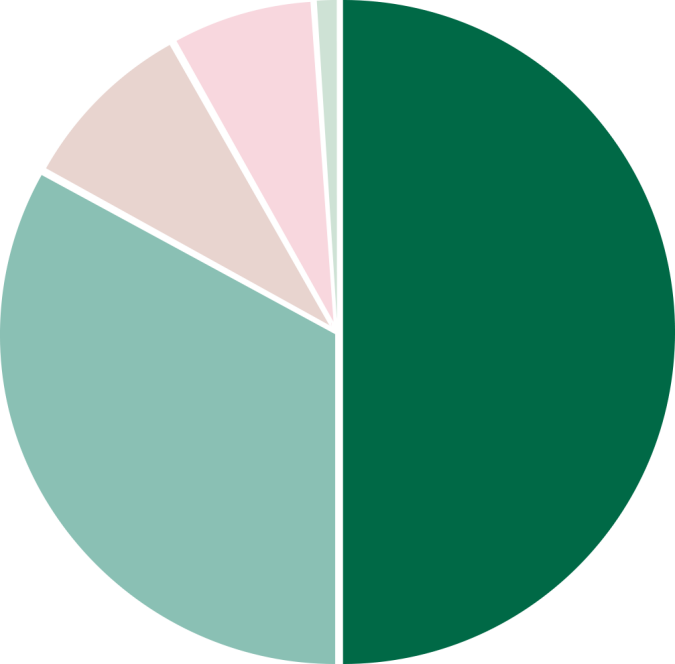

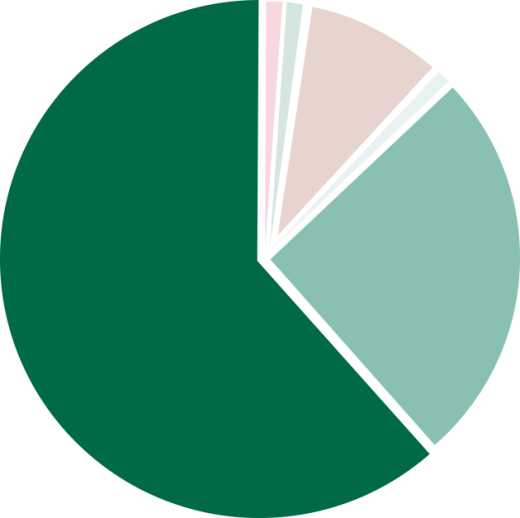

assortment classification 2023

based on turnover

2022

2.265

27

1.489

323

388

2.182

22

1.740

389

584

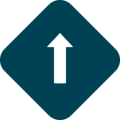

Carbon footprint 2023 vs. 2022

CO2 emissions (in tons)

Our greatest impact is in the products we bring to the market every day.

For that reason, we developed our assortment classification, which we use to establish the sustainability of specific products based on various criteria, such as legislation and guidelines. This tells us where we are and what steps we still need to take.

The movement towards more sustainable packaging is in full swing. And not only at Paardekooper. The government, entrepreneurs and consumers are also becoming more aware of packaging, the materials it is made of and the impact it has on the environment.

Paardekooper's Circular Business Team is therefore working on reusable packaging systems. We can then ensure that - in addition to our regular assortment - our customers have access to solutions where they can use the same products time and time again with total peace of mind.'

The Circular Business Team is the driver behind the transition from disposable to reusable packaging. Together with an interdisciplinary team of experts and in close collaboration with our divisions and partners, they work on developing innovative circular concepts for reusable packaging. These might involve total solutions for reusable tableware, cups and e-commerce shipping packaging including deposits, as well as pooling solutions for flower buckets and crates, for example.

Laws and regulations are constantly being tightened and consumers are reminded of their responsibility to choose better packaging.

For more than a decade, our independent scientific research agency founded by Dr Alan Campbell, The LCA Centre, has been the place where we test materials, conduct life cycle assessments and measure the impact of our packaging. Through this fact-based approach, we can make our products more sustainable, advise customers and respond to changing laws and regulations in a timely manner. With this data we can substantiate Green Claims, in which technical and specific knowledge at PHD-level and broad experience is necessary

The greatest impact of our organization is not in our buildings, but in the products we buy and sell. In 2023, we therefore made great progress in understanding the carbon footprint of our products.

‘Our carbon footprint is 8.6% lower than in 2022, largely due to the relocation of our horti division to a gas-free facility in Aalsmeer.’

1%

1,1%

1,2%

9,3%

38,5%

25,7%

22,8%

61,5%

61,7%

77,2%

Electric company and lease cars

Electricity

TRUCKS

company and lease cars

GAS

CO2-footprint 2023 (scope 1 and 2)

presented in percentages

In setting the new targets, we take into account what, for instance, customers expect from us. Customers are increasingly asking for Science Based Targets (SBT). These provide an in-depth science-based analysis of emissions and reduction plans. By working with these targets, we can be sure that our goals, in proportion to the nature and size of the company, will meet the Paris Climate Agreement. Paardekooper has already committed to the Science Based Targets initiative (SBTi). Once the target is set for the products (scope 3), we can get these targets approved.

studying other things that have an impact, such as hired transport, air travel and commuting. We then determine our target for these so-called scope 3 emissions. More about this in our 2024 sustainability report!

In 2023, we introduced an innovative reusable coffee cup that is perfect for both on-the-go and on-site consumption. The specially designed cup meets the requirements of coffee machines, offering a sustainable alternative to disposable coffee cups. The vending cup is fully compliant with SUP legislation.

Unique coffee vending cup

In 2023, we introduced paper bread clips as an alternative to traditional clips. Traditional clips are made from polystyrene, a harmful type of plastic, which falls into our ‘phase out’ category. This switch reduces our reliance on harmful materials. Moreover, the paper bread clips are suitable for machine use, which means they can also be used in industrial bakeries.

Paper bread clips

Last year, we introduced Gumtape, an innovative and sustainable tape solution. Not only is this tape very effective for sealing packaging, it is also plastic-free. This makes the tape easy to recycle. The tape contains a water-activated adhesive made from starch, making it a renewable and biodegradable alternative to traditional plastic tapes. The paper for this tape is sourced from FSC-managed forests.

New to the market: Gumtape

Our Horti division has replaced the PVC tubes our Christmas baubles are sold in with PET tubes. By doing this this packaging moves from the category ‘phase out’ towards ‘more conscious’.

From PVC to PET bauble tubes

Based on experiences from the pilots, we also improved the user-friendliness of our BI dashboard[MdV1] [SK2] . New products that are created are automatically assigned to the correct category of the assortment classification. This dashboard provides insight for both managing internally and engaging externally with customers. We now know that 37% of our products will be More Sustainable and 27% More Conscious by the end of 2023. In the Phasing out category, it is 2%. [MdV3] By 2024, our goal is to at least have a more sustainable alternative available in 75% of the product groups. Next year, these percentages will also be available for our Horti division after they migrate to a new ERP system.

For example, the pilots showed that the assortment classification is difficult to use without proper training. After these pilots, we therefore continued training account managers as well as our sales and support departments, such as procurement, product management and quality, on this method. In all, 90 colleagues received training.

For each product, we determine the environmental impact of material, production process, transport and the waste phase. In early 2024, we are finalizing the BI dashboard in which we calculate this footprint. for each product. We complete our footprint by also

As in previous years, we have determined our organization's carbon footprint based on our electricity and fuel consumption. Insight into the consumption of our stores has improved, making this data more reliable. This has resulted in a slight adjustment to our 2022 footprint. In 2023 we were able to reach a reduction of 8,6% compared to 2022. This is mainly due to the move of our horti division to a shared gas free building in Aalsmeer, because of this we used 34% less gas. Like last year, we can see an increase in the number of electric cars in our fleet. Because of this increase we were able to reduce the petrol and diesel use by 17%.

To further reduce our carbon emissions in the coming years, we recalibrated our reduction target in 2023.

Paardekooper will reduce the carbon emissions from its own operations (scope 1 and 2) by 50% in 2030 compared to 2022.

We aim to achieve this by reducing our electricity and gas consumption. For example, by purchasing green electricity and significantly reducing the fuel consumption of our business kilometres. Just last year 16 of our truck drivers were trained on driving economically. In 2024 the other drivers will be trained and we hope to see this in our footprint next year.

In 2023, we drew up an action plan and targets for our organization (scope 1 and 2). And we obviously look at the products we buy and sell, because this is the area where we have the most impact. This is why, in 2024, we calculate the impact of our products. By doing this we can also set measurable goals for them.

Rooftop garden of our new Horti facility in Aalsmeer

Over the next few years, we aim to halve our organization's carbon emissions.

Dit duurzaamheidverslag over 2023 is ingedeeld in zes thema’s, die bepaald zijn aan de hand van een dubbele materialiteitsanalyse. Daarbij hebben we zowel gekeken naar de impact van Paardekooper op het milieu en de maatschappij als naar de duurzaamheidsrisico’s en kansen voor Paardekooper.

Materialiteitsanalyse uitgevoerd om onze leidende thema’s te bepalen

Scroll down

3/6

ENVIRONMENT

Reducing environmental impact in the chain

Making the assortment more sustainable

is something we do together

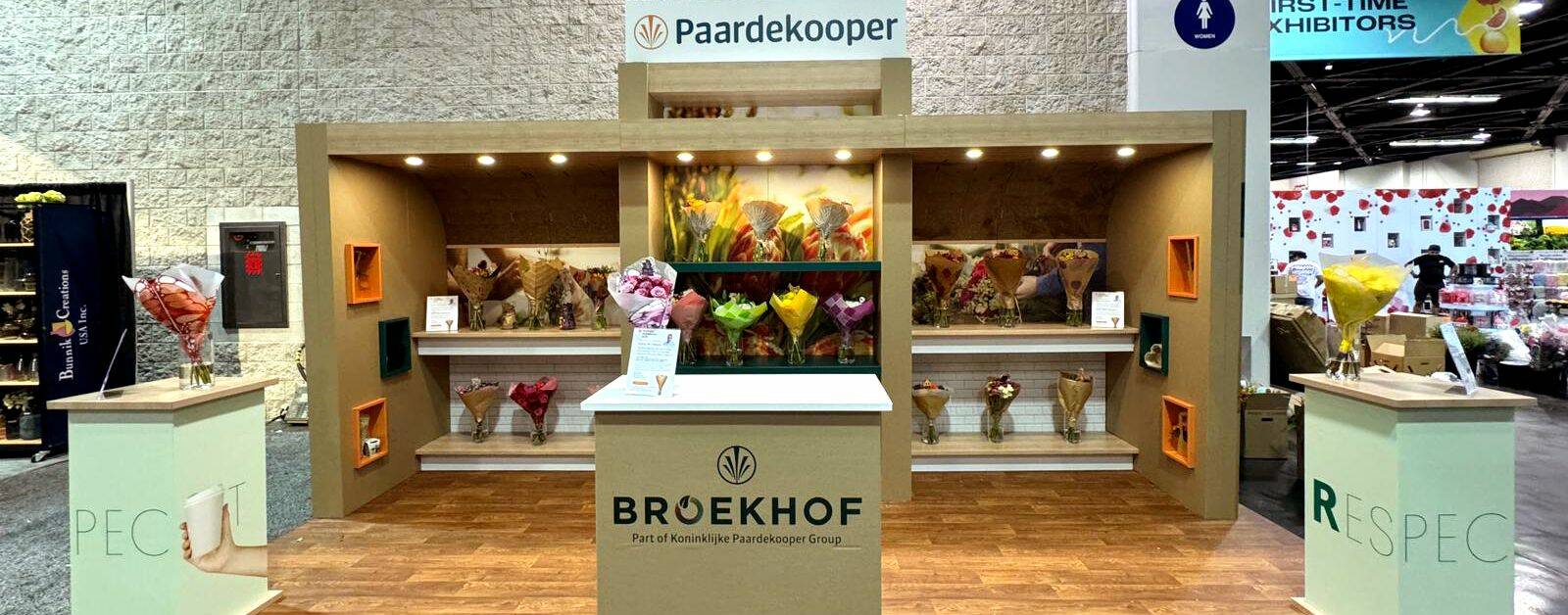

At the Global Fresh Produce and Floral Show in Anaheim California, Broekhof USA presented itself in a stand made entirely of recycled cardboard. Colleague Dr Alan Campbell from The LCA Centre gave a workshop on 'Transforming Floral Packaging for Sustainability and Profit’.

In 2022, we focused on setting up and implementing the assortment classification in our organization. In 2023, the focus was on its applicability towards customers.

We conducted pilots with an initial group of account managers at six customers. This gave us insight into how our employees can easily apply this tool, allowing us to roll out the assortment classification to as many customers as possible.

Circular chain partner

Floral Show

A look behind the scenes

at The LCA Centre

Customer pilots

testing in practice

In 2023, we formulated an action plan and objectives

for our organization.

Paardekooper takes its responsibility to reduce its environmental impact. We have, for instance, been working for years to make buildings and shops more energy efficient.

We continuously map our impact in terms of CO2. This allows us to make informed choices and actually measure the improvements. Focusing on the theme of ‘reducing the environmental impact in the chain' will help us further reduce our impact - together with our suppliers and customers.

credit Willeke Machiels - Fitchd

credit Rogier Boogaard

Data dashboards

Science Based Targets (SBT)

The footprint of our products

Scope 1 en 2 CO2 emissions of our organization.

3%

22%

32%

43%